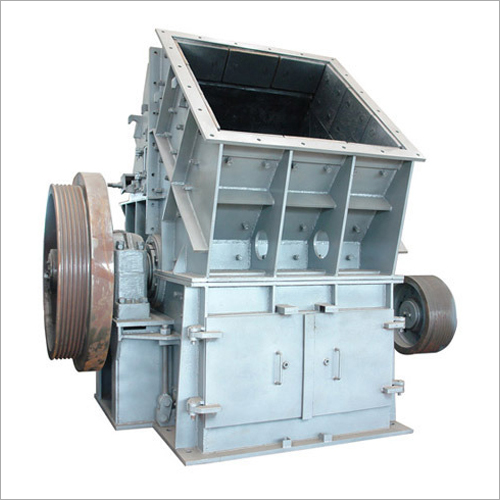

Hammer Crusher

MOQ : 1 Unit

Hammer Crusher Specification

- Motor Power

- 15 kW

- Weight

- Approx. 2.5 Tons

- Color

- Yellow & Black

- Processing Type

- Crushing

- Frequency

- 50 Hz

- Application

- Used for crushing stone, coal and ores

- Automatic Grade

- Automatic

- Thickness

- Up to 12 mm

- Noise Level

- Moderate

- Control System

- Electric Control Panel

- Capacity

- 10-15 TPH

- Material

- Mild Steel

- Voltage

- 415 V

- Size

- Standard Industrial Size

- Installation Type

- Stationary, Foundation Mounted

- Discharge Size

- Less than 25 mm

- Lubrication

- Grease Lubricated Bearings

- Hammer Quantity

- 4-6 pcs

- Crushing Ratio

- High

- Frame Type

- Heavy Duty Welded Steel

- Rotor Diameter

- 600 mm

- Feeding Size

- Up to 200 mm

- Drive Type

- Belt Driven

- Rotating Speed

- 1400 RPM

- Safety Features

- Overload Protection, Emergency Stop

- Operating Mode

- Continuous

Hammer Crusher Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 4-5 Days

- Main Export Market(s)

- South America, Western Europe, Central America, Eastern Europe, Middle East, Asia, North America, Australia, Africa

- Main Domestic Market

- All India

About Hammer Crusher

Hammer Crusher finds most common application for construction & mining industries for reducing size of large stones. It is equipped with a have duty motor which manages action of hammer via wheel-pulley assembly. This crusher is made of tough metal alloy and is provided with coating of superior quality paint for preventing corrosion. It can crush hardest of stones while giving small size stones. Hammer Crusher is also employed in energy production sector for preparing materials that are used in boilers & coking plants. It is known to give flexibility of adjusting crushing area as per user's need.

Robust Performance and Design

Constructed from mild steel, the Hammer Crusher boasts a heavy-duty welded steel frame that ensures durability and reliable operation in industrial environments. The machines large rotor diameter and multiple hammer configuration ensure high throughput and effective material reduction, making it well-suited for continuous, large-scale processing.

Precision Control and Safety

An integrated electric control panel allows automatic operation, maintaining consistent performance while minimizing manual intervention. Essential safety features, including overload protection and an emergency stop, prioritize operator safety and machine longevity during regular use in demanding applications.

FAQs of Hammer Crusher:

Q: How does the Hammer Crusher process materials such as stone, coal, and ores?

A: The Hammer Crusher processes materials by continuously feeding them via the inlet, where rotating hammers powered by a 15 kW motor break down the feed (up to 200 mm) into smaller pieces. The crushed material is then discharged through the bottom, achieving a final size of less than 25 mm.Q: What benefits does the heavy duty welded steel frame offer?

A: The heavy duty welded steel frame provides superior structural integrity, reducing wear and vibration during operation. This construction ensures longevity, reliability, and safe operation in harsh industrial environments.Q: When is regular maintenance required for the Hammer Crusher?

A: Regular maintenance intervals depend on operating conditions, but key components like the grease-lubricated bearings should be inspected and greased routinely as recommended in the user manual to ensure smooth, efficient performance and to prevent premature wear.Q: Where should the Hammer Crusher be installed for optimal performance?

A: The Hammer Crusher is designed for stationary, foundation-mounted installation. It should be placed on a stable, level surface in an industrial setting, with sufficient space around it for operation and maintenance.Q: What is the operational process flow of this Hammer Crusher?

A: Material is introduced into the machine, where hammers attached to a rapidly rotating rotor strike and crush it. The processed material passes through a discharge grate for size control, and the automatic electric control panel manages continuous operation for consistent output.Q: How does the integrated safety system protect operators?

A: The crusher features built-in safety mechanisms such as overload protection and an emergency stop button. These systems immediately halt machine operation in case of anomalies, effectively safeguarding personnel and minimizing the risk of machine damage.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS